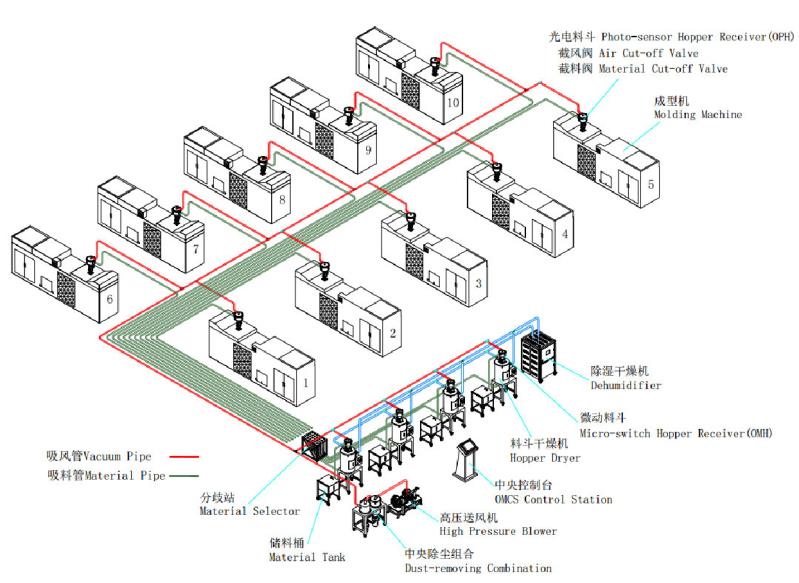

Utilizing the method of vacuum conveying, Orste Central Material Feeding/Conveying System (OMCS) transports plastic materials from storage silos to the central dehumidifying & drying system through centralized piping, and then convey the dried material to each molding machine.

189-4860-6110 / 0769-82020256Utilizing the method of vacuum conveying, Orste Central Material Feeding/Conveying System (OMCS) transports plastic materials from storage silos to the central dehumidifying & drying system through centralized piping, and then convey the dried material to each molding machine. OMCS is suitable for the integrity of the material of huge capacity, eliminates waste and improves the cost effectiveness of the factory.

Product Introduction

u7cc彩票Utilizing the method of vacuum conveying, Orste Central Material Feeding/Conveying System (OMCS) transports plastic materials from storage silos to the central dehumidifying & drying system through centralized piping, and then convey the dried material to each molding machine. OMCS is suitable for the integrity of the material of huge capacity, eliminates waste and improves the cost effectiveness of the factory.

Continuous auto-operation

u7cc彩票Various dosing & mixing for different colors and materials

Effective instant recycling which can mix regrind and new material flexibly

Offer you the most flexibility to easily be expanded or modified equipment, make sure your production safer and more reliable and keep the best working environment.

OMCS Control Station

u7cc彩票Ideal design of integrating the monitoring panel and the control panel.

u7cc彩票Friendly interface and accurate control.

Operating and monitoring by a single personnel and can be linked with a PC.

u7cc彩票Conveying time, material types, and pipe cleaning time of each station are adjusted by the control station.

Displaying panel shows you how stations, dryers and storage silos work, such as on/off, full or lack of material, and material types of each station.

u7cc彩票Extensive interface allows easy expansions up to 40 stations for future demands.

Compact and durable.

u7cc彩票Microprocessor touch-style control panel

Operating status:

Display the operating status of machines.

u7cc彩票Set-up status:

Display the set up status, such as working stations, material types, material conveying time, and pipe cleaning time.

Abnormal:

Display abnormal machines and material type.

u7cc彩票“OMCS” Control Unit

u7cc彩票Ideal design of integrating the monitoring panel and control panel, User-friendly interface, Compact & Durable, Small space to make more productive use of factory floor space.

High-pressure Blower

u7cc彩票Pressure air adjustable.

u7cc彩票Maximum conveying distance can be 150 meters.

Suitable for conveying the material of large capacity.

u7cc彩票Material Selector

Stainless steel made to avoid pollution of materials. Quick coupling devices for quick set-up or easy disconnected with pipes.

Dust-removing Combination: Vortex Cylone & Pulse Dust Collector

u7cc彩票Collect dust from the conveying system efficiently.

Double protections for high-pressure blower in operation. Easy to maintain: only to change the filter on time and clean conveniently.

Dedicated and compact design.

u7cc彩票Material Cut-off Valve: Stainless steel made, durable device design.

u7cc彩票Air Cut-off Valve: Stainless steel made, reliable device design.

Compression Couples: Stainless steel made, connect pipes to construct the completely-closed central vacuum conveying system.